Mixer for Injection Moulding

Injection Moulders must deal with many different moulding tools, polymer types and formulations and colour additives and master batches. Production rate, yield and high quality products are key to their success. The probability of success is greatly increased by installing an SMN static mixer injection moulding mixing nozzle direct upstream the moulding-tool.

Download Inquiry Sheets

Product Details

SMN-Mixing-Nozzle

An SMN mixing nozzle consists of a nozzle body with a built-in static mixer set, which consists of eight (8) SMN mixing elements as standard. The nozzle is attached to the cylinder of the injection moulding machine on the inlet side with an adapter. The connection to the mould is made with the injection nozzle. The whole nozzle is heated and equipped with a thermocouple.

SMN

Mixing set with 8 mixing elements (ME)

SMN-GPD

Mixing set with 7 mixing elements (ME) and 1 grid protection device (GPD)

SMN-SMF

Mixing set with 6 Mixing elements (ME) and 1 Filter (SMF)

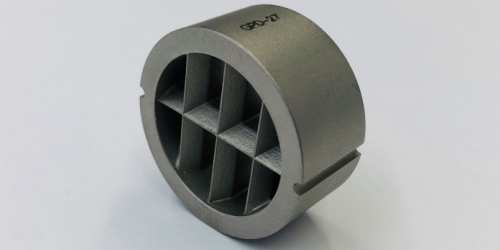

GPD

Grid-Protection-Device (GPD)

Protects the SMN static mixing elements from possible damage due to a "Cold Start" event when a slug of unmelted polymer under high pressure strikes the face of the mixing elements and damages them. The GPD is extremely strong and prevents unmelted polymer from striking the mixing elements.

SMF

Filter (SMF)

Protects the mixing elements, nozzle tip, hot runner system and tooling from clogging and damage when processing regrind material by filtering unwanted solids (e.g. aluminium parts, pebbles, staples, etc.) in the polymer melt that a magnetic separator does not catch. The SMF Filter also holds back partially melted pellets until they are fully melted.