General Mixing

Based on our many years of experience in designing and fabricating static mixers, Stamixco static mixers are used in a wide variety of applications. Depending on parameters such as volumetric and viscosity ratios, density and concentration of the materials to be mixed, the ideal mixing geometry is selected. Issues to consider include: are the fluids soluble in each other or do they need to be dispersed?; are the gases to be processed soluble in the liquid processed and in what ratios? Examples are turbulent gas mixing for flue gas cleaning units or ozonisation in water treatment plants.

The experience of Stamixco guarantees the best solutions in both laminar and turbulent flow applications.

Download Inquiry Sheets / Data Sheets

Housing for the mixers

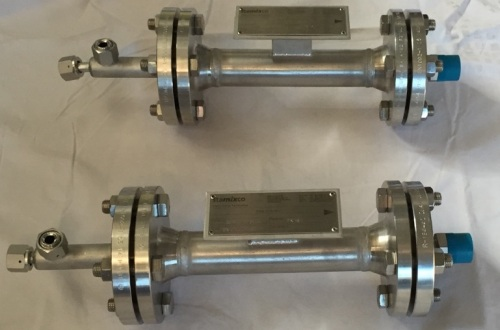

Our mixers can be supplied as a mixer insert without housing or with housing as a complete assembly. The housings for the mixers are always designed and manufactured to customer specifications. This allows us to meet customer requirements in terms of design, connections, pressure ratings, etc.

Below you will find pictures of already realized mixer housings:

System Engineering

Stamixco also offers customised pumping, control and dosing systems. We develop, design and manufacture the systems according to your requirements.

Below you will find pictures of already realized systems:

GXM

GXM Mixer

GVM

GVM Mixer

Flowte-B

Flowte-B Mixer

Inline Mixer / Pipe Mixer

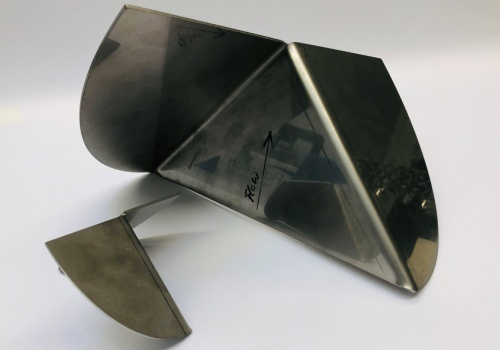

The stainless steel pipe mixers with permanently installed mixing elements are particulary suitable for mixing 2-component synthetic resin systems. These pipe mixers made of stainless steel consist of alternately following left- and right-turning mixing elements, which are soldered in a tubular mixer housing over the entire length by a special soldering process.

Helical Mixer

Helical Mixer